OVERVIEW OF MACHINE SHOP SERVICES

Ontario Crank Services provides the highest quality of service, providing engine rebuilding and machine shop services to a variety of powersport and industrial dealers across Ontario.

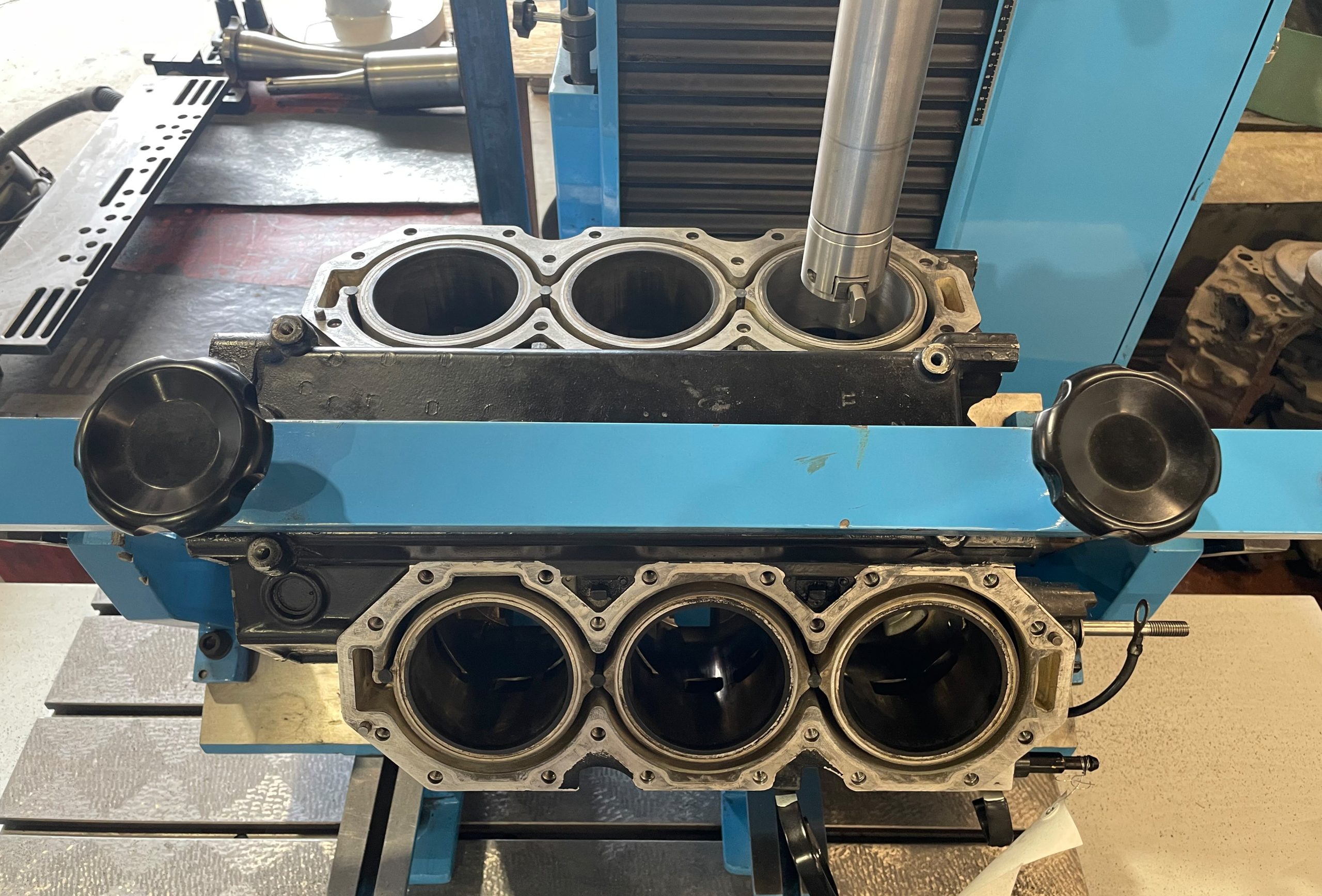

All makes and models of inboard marine engines, outboard marine engines and personal watercraft are rebuilt by Ontario Crank Services

Long block engine rebuild includes timing cover, oil pan and rocker covers installed with balance of gaskets supplied.

Complete engine rebuild includes the above, with your exhaust manifolds, intake manifold, alternator, starter and all accessories, mounts, hoses, and electrical units installed.

Your engine must be in re-buildable condition. Replacement of cores (heads and blocks) and welding is additional to the cost of rebuilding your engine.

Ignition, carburetion, oil, filter, outdrives or transmissions are not included in the cost to rebuild the engine. Pricing is for the rebuilding of internal engine assembly only. (Pricing is available for items not included.)

OCS Marine Services’ engine rebuilds are warranted for twelve to twenty four months from the date installations.

OCS MACHINE SHOP SERVICES INCLUDE BUT NOT LIMITED TO:

- CAM BEARING INSTALLATION

- STRIP AND CLEAN

- CRANKSHAFT GRINDING

- CRANKSHAFT POLISHING

- FIT PIN BUSHINGS

- HONING AND BORING

- MAGNAFLUXING

- MILLING

- PRESS WORK

- RECONDITION RODS

- CYLINDER HEAD WORK

Cam bearing installation involves cleaning the camshaft bore, lubricating and placing the new bearings, ensuring precise alignment and seating, then securely pressing or tapping them into position. Properly installed cam bearings support smooth camshaft rotation, optimizing valve timing and engine performance.

The engine block is dismantled, separating components like pistons, connecting rods, and the crankshaft. Once disassembled, each part undergoes a meticulous cleaning process to remove dirt, grease, and any built-up deposits. Various methods like jet washing, solvent cleaning, and media blasting may be employed depending on the level of contamination. After cleaning, components are inspected for wear or damage, and necessary repairs or replacements are made.

The crankshaft is mounted on a specialized grinding machine that rotates the crankshaft while abrasive grinding wheels remove material from the crankshaft’s journals and rod bearing surfaces. The grinding process is carefully controlled to achieve the desired dimensions and surface finish while maintaining proper alignment and concentricity.

The crankshaft is mounted on a specialized polishing machine, and abrasive polishing belts or wheels are used to remove a thin layer of material from the journal surfaces. This removes any surface imperfections and creates a smooth, uniform finish.

Using a milling machine, the wrist pin bores are carefully enlarged to the required diameter. Bronze bushings are then pressed into the milled bores, ensuring they are seated correctly. The inner diameters of the bushings are reamed and honed for a precise wrist pin fit.

Boring and honing are crucial machining processes for powersports and marine engines, restoring or modifying cylinder bores for optimal performance. Cylinders that can be bored and honed include those in various engines like outboard motors, jet skis, motorcycles, and other marine and powersports vehicles. Boring enlarges the bore diameter using a precision machine, typically to fit oversized pistons or repair damage. Honing follows to create a smooth surface, ensuring proper piston ring seal and reducing friction.

Magnafluxing, also known as magnetic particle inspection, is a non-destructive testing method used to detect surface and subsurface cracks in engine blocks and other metal components. The process involves magnetizing the engine block by passing an electric current through it or by using a strong magnet. Then, a special magnetic particle solution is applied to the surface of the block. If there are any cracks or defects present, the magnetic particles will be drawn to these areas, forming visible indications. After a specified dwell time to allow the particles to gather, the surface is wiped clean, leaving behind a pattern of accumulated particles that reveal the location and extent of any defects.

Milling work on powersports and marine engines involves using specialized milling machines to modify the cylinder head and engine block surfaces for various purposes. This process can include milling the cylinder head to increase compression ratio, improve airflow, or correct warpage. Additionally, milling the engine block surface can be done to achieve proper deck height, ensure a flat mating surface for the cylinder head, or enhance piston-to-valve clearance. The milling machine precisely removes material from the specified areas, taking into account the engine’s design tolerances and performance goals.

Press work in powersports and marine engines involves the controlled application of force to assemble or disassemble components. This encompasses tasks such as pressing bearings, bushings, gears, and shafts into place, as well as removing stubborn or seized parts. Hydraulic or mechanical presses, along with specialized tooling, are utilized to ensure precise application of force while minimizing the risk of damage to components.

The big end of the rod is resized by honing or boring to restore its original dimensions, ensuring a perfect fit with the crankshaft. If necessary, new bushings are installed in the small end and reamed to the correct size. The rods are then checked for straightness to ensure proper operation after installation.

Our cylinder head services encompass a range of tasks, including thorough disassembly, cleaning, and meticulous reassembly. We conduct valve grinding and lapping to ensure optimal sealing, and we’re equipped to replace valve guides, installing bronze guides when necessary. Additionally, we offer spring seat cutting, accommodate oversize valves, and perform surface grinding to restore proper dimensions and finish. This comprehensive approach ensures that cylinder heads receive the necessary attention for improved performance and longevity.

Our goal at OCS marine service is to provide you with complete service for your boat, PWC, ATV and snowmobile, with our trained and insured staff.

Info

- (705) 329-7222

- Monday - Friday 9:00am to 5:00pm